Extremely durable seams

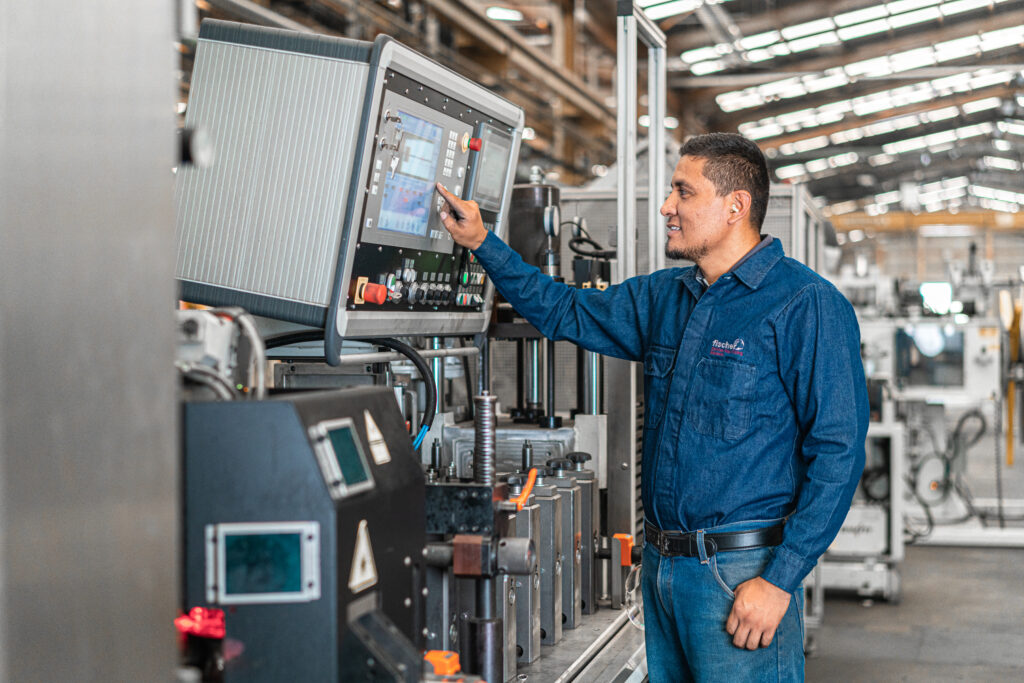

The fischer group is one of the pioneers of laser welding in tube production. The method allows precise connections of first-class quality, even with small wall thicknesses.

The fischer specialists took on the challenge in the early 1990s already. They were thus able to take the complex joining process to an extremely robust level that had been barely conceivable just a few years before.

Laser welding has been optimized to the extreme case that the tubes fail in the base material – before

the weld seam breaks!

With the “Laser-Plus welding process” introduced in the 2000s, the fischer group has made a name for itself among demanding hydroforming customers in particular. It ensures process reliability even for extreme forming without intermediate annealing.

Tubes as well as components and subassemblies are also welded reliably at the fischer group.

All materials reliably welded

In addition to the process, the range of materials has gradually expanded over the years. Today, the complete range of materials is reliably welded and processed, from ferritic stainless steel through austenitic materials and duplex stainless steels to nickel-base alloys and titanium materials.

Laser welding

Wall thickness: 1.5 mm

Height of the welded root < 0.127 mm

High frecuency welding

Wall thickness: 1.5 mm

Height of the welded root < 0.15 mm